Recently, organic-inorganic hybrid perovskite type (CH3NH3PbI3) solar cells have a series of high absorption coefficients, balanced electron hole mobility, adjustable bandgap, extremely high quantum luminescence efficiency, and large defect tolerance. The characteristics make the photoelectric conversion efficiency of such batteries exceed 20% in just 5 years. However, such batteries are prone to hydrolysis in a wet environment and cause the batteries to fail. The long-term stability of the batteries has become a bottleneck and a difficulty for commercialization thereof.

Recently, the research team of “Nanostructure and Low-dimensional Physics†of Peking University led by Prof. Yu Dapeng of the School of Physics has made new progress in this field. The team's associate professor Zhao Qing and others designed a new structure for perovskite batteries. Long-chain hygroscopic PEG molecules were introduced into the perovskite material light-absorbing layer as a polymer backbone. The long-chain PEG molecules formed a three-dimensional network to make calcium. The film quality of the titanium ore material is significantly improved, the photoelectric conversion efficiency and repeatability of the battery are significantly improved, and the maximum efficiency is up to 16%.

The battery can be completed at a temperature of 100 degrees Celsius and the preparation method is simple and easy to promote. Due to the superabsorbent nature of PEG molecules, the stability of polymer-framed perovskite cells in humidity environments is significantly improved: no packaged battery devices exhibit more than 300 hours in an extremely humid environment (70% relative humidity) stability.

Not only that, the polymer-framed perovskite battery exhibits a magical "self-healing" function: Perovskite materials and batteries can be quickly self-repaired back to the original battery state and battery efficiency within one minute after being hydrolyzed. Studies have shown that due to the strong interaction between PEG and the methylamine ions in the perovskite material, the lead iodide and methylamine iodine after hydrolysis can be regenerated into perovskite materials in situ, exhibiting both the material and efficiency of the battery. The "self-healing" feature.

The novel polymer framework structure greatly enhances the permanganate battery's tolerance to water destructive and humid environments, greatly improves the stability of the battery under the humidity environment, and solves the problem that the perovskite battery is afraid of water vapor and battery efficiency. The application problems, which will rapidly decrease in wet conditions, exhibit a magical self-repairing function, which provides a new idea for the commercialization of perovskite batteries in the future, and has important scientific significance and application value.

Material: SS304, SS316

Weave type: Plain weave, Twilled weave, Dutch weave

Features: Corrosion-resisting, Wear-resisting

Uses:Mainly used for filtering and sieving, extensively used in petroleum, chemical industry, enviroment protection,

mine, airspace, paper-making, electronic, metallurgy etc.

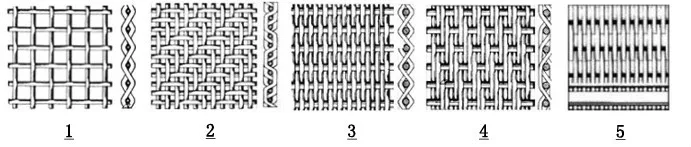

Weave type explanation

1. Plain Weave: also called tabby weave, linen weav or taffeta weave, is the most basic type of weaves.

In plain weave, the warp and weft are aligned so they form a simple criss-cross pattern. Each weft thread

crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under

the warp threads that its neighbor went over, and vice versa.

2. Twill Weave: In a twill weave, each weft or filling yarn floats across the warp yarns in a progression of interlaces

to the right or left, forming a distinct diagonal line. This diagonal line is also known as a wale. A float is the portion of

a yarn that crosses over two or more yarns from the opposite direction.

3. Plain Dutch Weave: similar with plain weave, just the weft and warp wire have different wire diameter and different mesh size.

4. Twill Dutch Weave: similar with twill weave, just the weft and warp wire have different wire diameter and different mesh size.

5. Reversed Dutch Weave: difference from standard Dutch weave lies in the thicker warp wires and less weft wires

Stainless Steel Series,Stainless Steel Wire Mesh,Stainless Steel Crimped Wire Mesh,Stainless Steel Window Screen

Anping Shengjia Hardware Mesh Co.,LTD , https://www.oilshaleshakerscreen.com